At Deluxe Motor Electrical Repair, we stand as a beacon of excellence in the realm of electrical motor repair and services. With a legacy of expertise and a commitment to unparalleled service, we cater to various industries, ensuring the seamless operation and maintenance of motors, pumps, and gearboxes. Our dedication to quality, innovation, and customer satisfaction has positioned us as a trusted partner in the domain of motor repair and electromechanical solutions.

Deluxe Motor Electrical Repair is dedicated to delivering superior motor repair and maintenance services, employing cutting-edge techniques and a skilled workforce.

Our vision at Deluxe Motor Electrical Repair is to be the foremost leader in the electrical motor repair industry, setting benchmarks for innovation, efficiency, and customer-centric solutions.

Is your motor experiencing electrical problems? Trust our skilled technicians to diagnose and repair electrical issues efficiently. At [Your Company Name], we specialize in comprehensive motor electrical repair services, ensuring your equipment operates at peak performance.

Our Generator Repair & Services are a comprehensive suite tailored to meet your diverse needs and ensure top-notch generator functionality:

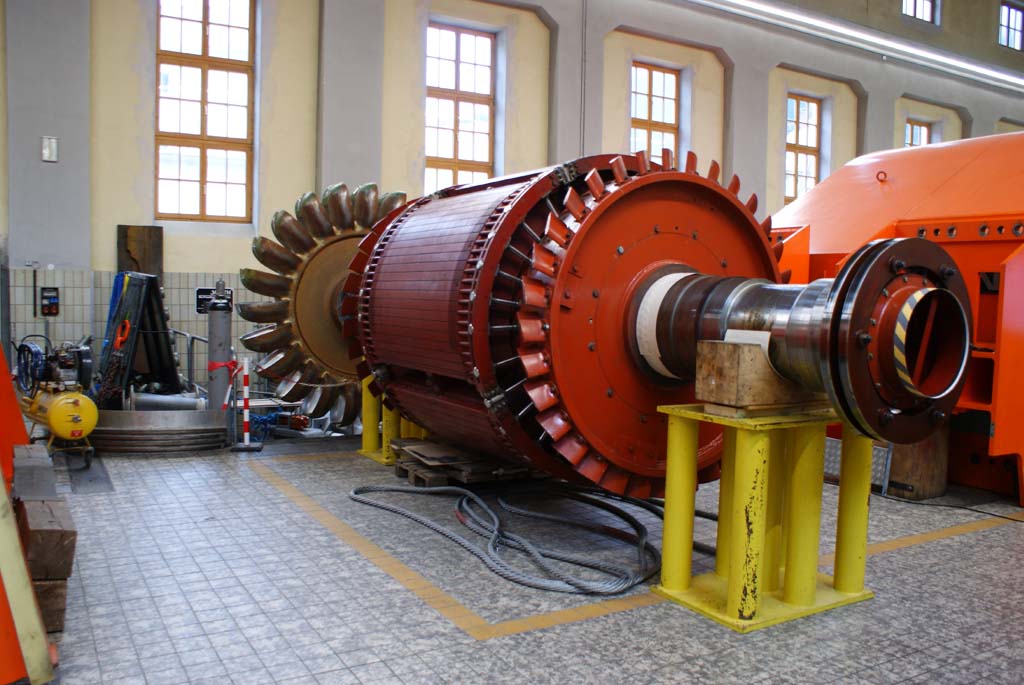

We specialize in elevating the efficiency of Thermal & Hydro Generators, amplifying their capacity by up to 150 MW.

Crafting Stator Coils ranging from 3.3 KV to 15 KV, accommodating generators up to 250 MW.

Proficiency in manufacturing and re-insulating Rotor Field Coils, ensuring optimal performance.

Skilled in the meticulous assembly of critical components like Stators, Cores, and Coils, ensuring precision and reliability.

Comprehensive testing protocols and seamless commissioning processes to guarantee generator functionality.

Extensive overhauls to boost performance and extend the operational lifespan of generators.

Utilizing cutting-edge cryogenic cleaning methods for optimal maintenance and cleanliness.

Expertise in replacing generator bearings to ensure smooth and efficient operations.

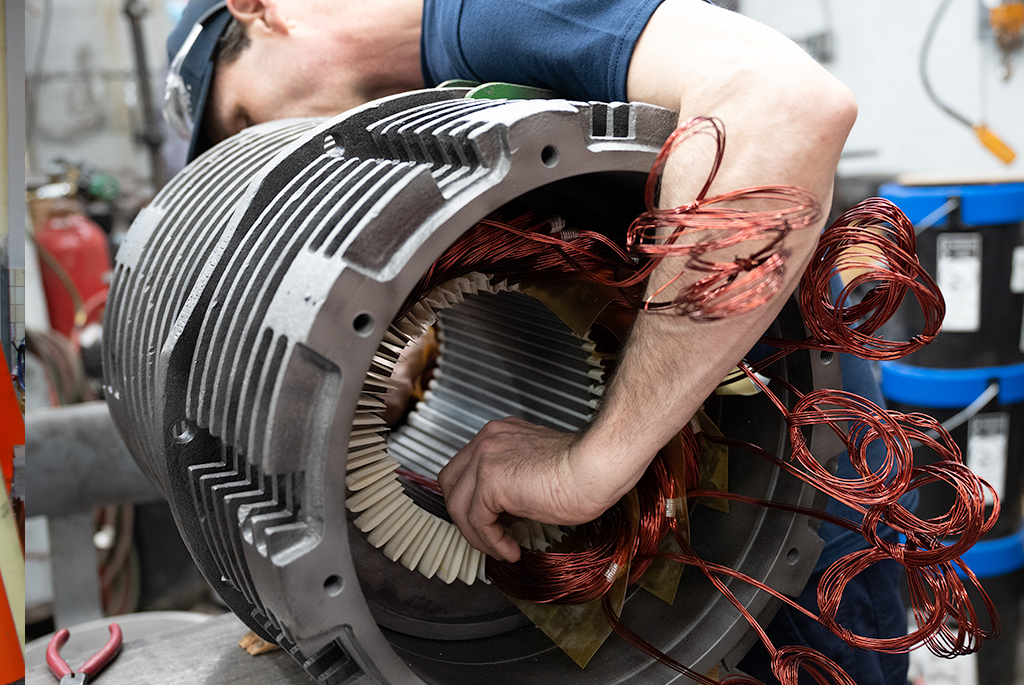

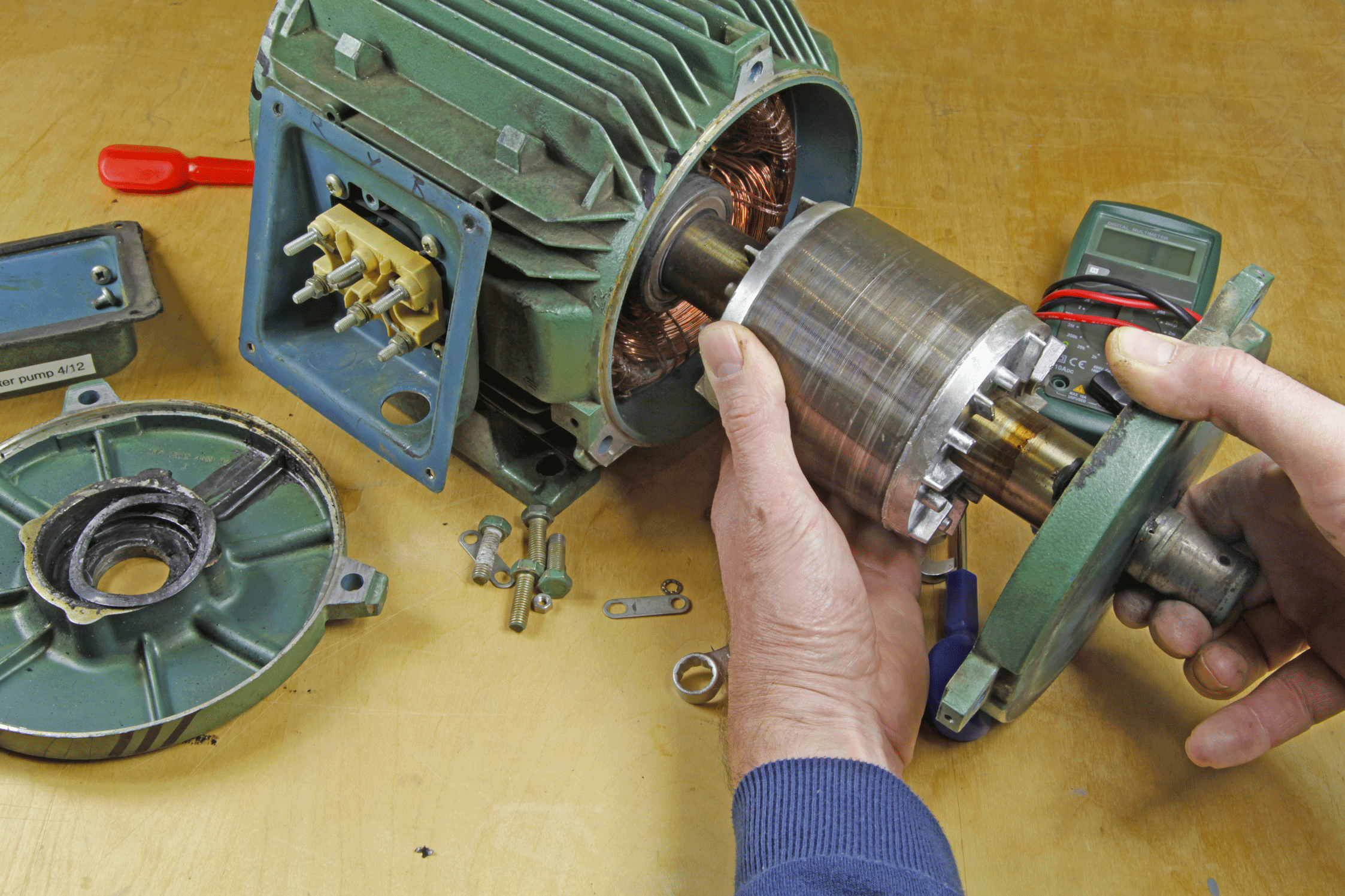

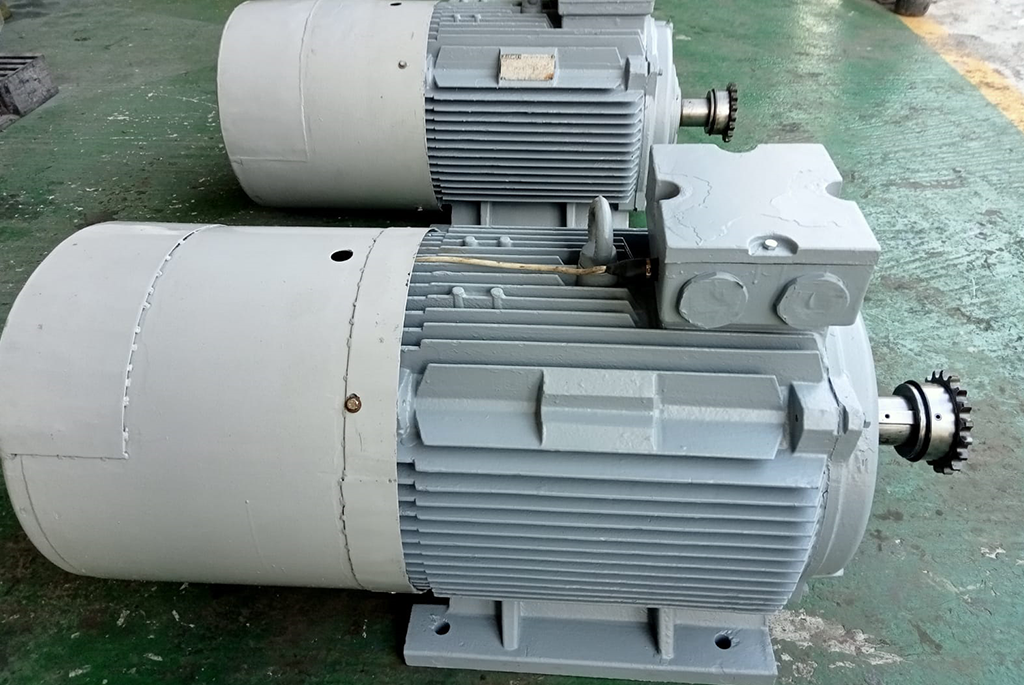

We specialize in comprehensive motor repair and rewinding services catering to various needs:

Our Cryogenic CO2 cleaning service offers an environmentally friendly, non-abrasive method for precise cleaning across various industries. It's efficient, eco-conscious, and extends machinery life.

Comprehensive range of balancing machines for different types of equipment ensuring optimal performance.

Our product offerings range from Low to High Voltage Current and Voltage Transformers, Outdoor Oil Cooled units, Special Purpose Transformers, DC Transformers, and High Voltage Testers.

Detailed alignment for horizontal and vertical/flange-mounted machines. Cutting-edge instruments ensure accurate measurements and fault analysis, aiding in smooth operations.

Restoration, Rewinding, and Redesign of A.C. Stators and Rotors up to 13.8 KV. Crafted to original specifications, tested to international standards.

Armature, Magnet Frame Restoration, Manufacturing of spare coils for D.C. Motors and Generators.

On-site Coil Installation by our Engineers, cost-efficient and time-saving services.

Adherence to ISO Quality Standards ensures precise assessment of windings and stator core. Complete testing, meticulous documentation, and meticulous inspections assure quality surpassing the original.

Customized Coils for Electrical Motors & Generators up to 13.8 Kv, tailored to your machine's unique specifications.

We produce spare coils to scale, from hydro generators to oil rig machines, facilitating swift replacements, avoiding extensive downtime.

Deluxe Motor Electrical Repair stands as a leading company in the UAE, catering to a broad spectrum of industries. Our expert engineers serve various sectors like Water Authorities, Steel Industries, Chemical Plants, Textile, and more. We offer on-site services including Repairs, Maintenance, Vibration Analysis, and Thermo graphic Surveys with quick same-day collection and delivery.

Our Electro-Mechanical Engineers provide extensive in-house and on-site services, fulfilling industry needs comprehensively.

For comprehensive electrical motor services, whether repairs, replacements, or new installations, our team is ready to assist. Reach out to us for a FREE, no-obligation quote or detailed information about our offerings.

At Pump & Compressor Repair & Services, we understand the urgency of pump breakdowns. Specializing in emergency repairs of sewage and water pump systems, our comprehensive repair solutions ensure quick restoration. Our stocked warehouse and repair workshop have a wide array of replacement pump parts. If unavailable, we swiftly source the needed parts for your convenience.

Our expert team excels in maintaining and repairing various pump types, offering tailored and competitively priced maintenance services. Timely repairs prevent serious damages, offering peace of mind and avoiding costly property damage due to leaks. We also provide service agreements, prioritizing your response, parts, and labor needs.

Catering not just to domestic markets but also commercial and building services industries, we provide pump repairs, overhauls, and rebuild services. Our comprehensive maintenance extends to commercial, industrial, and domestic pumps, ensuring efficiency and risk reduction.

We stock thousands of parts and offer repair services for various pump types including DAB, ABS, booster, agitator, submersible, irrigation pumps, and more.

Our on-site and workshop maintenance and repair services aim to swiftly resolve issues without disrupting your operations. Our engineering team excels in identifying and fixing pump issues promptly. If a pump is beyond repair, we suggest suitable replacements within your budget, ensuring competitive pricing for replacements.

We supply, install, and repair leading brands such as ABS, EBARA, GRUNDFOS, KSB, LOWARA, WILO, CLARKE, FLYGT, FRANKLIN, and XYLEM for booster, agitator, submersible, dewatering, and sump pumps.

Choose Pump & Compressor Repair & Services for expert, efficient, and cost-effective pump repairs and maintenance.

The Motor Offline Test involves several sophisticated procedures to assess and maintain the health of stator windings, ensuring optimal performance and longevity of motors. Here’s an overview:

This test improves upon conventional core flux testing by applying 4% flux instead of 100%, making it more practical for large generators. By measuring voltage generated in a flux sensor moved along the core periphery, it detects laminar shorting, revealing defects as variations in measured waveforms.

This method, based on IEEE standards, evaluates insulation resistance (IR) values and the Polarization Index (PI) for assessing insulation dryness or wetness. For modern insulation types like Class F, IR values remain high due to minimal moisture penetration, requiring additional parameters for evaluation.

Studies on leakage currents in insulators indicate an increase in odd harmonics (3, 5, 7, 9) with contamination or aging. For stator insulation with non-linear materials, this analysis uses FFT spectra to detect partial discharges and assess insulation conditions.

Following CIGRE 552 & IEEE 286, this test examines insulation health, focusing on stator coils. It evaluates variations in tan delta and capacitance curves to detect resin cure, delamination, moisture presence, and dielectric loss.

Adhering to IEEE 1434 and IEC standards, this test detects PD inception/extinction voltages, providing insights into insulation conditions. It uses PD signals at various frequencies for accurate analysis and maintenance guidance.

Primarily for LT motors, this test checks inductance, capacitance, and phase angles, aiding in troubleshooting issues like interturn faults, cable faults, or phase unbalance.

This test measures the balance in three phases using a micro-ohmmeter, post-rewinding or for trend analysis to detect developing high resistive joints.

Following IEEE 522, this test assesses inter-turn insulation health by measuring repetitive voltage surges and comparing their characteristics among different phases, revealing shorted turns or developing interturn faults.

These tests, utilizing various specialized equipment and adhering to international standards, collectively ensure a thorough evaluation of motor insulation, windings, and core, offering insights into potential issues and guiding maintenance strategies.

The Motor Online Test incorporates various sophisticated analyses ensuring optimal motor functionality while the machinery is in operation:

This process involves collecting motor current and voltage patterns at a fixed load using a high-resolution data collector, often coupled with vibration spectrum analysis. Employing time-based assessments, FFT, and frequency peak detection, algorithms detect conditions such as static/dynamic eccentricity, soft foot issues, or bearing defects caused by electric currents. For slip-ring motors, identification of rotor asymmetry is possible. Additionally, it analyzes line parameters like harmonics, current/voltage imbalances, and efficiency.

Using ISO 22096:2007 standards, this test identifies bearing defects such as spalling in roller balls or inner/outer raceways. The severity of these defects is determined, and an action plan is recommended. Acoustic emissions, employing the "Shock-pulse" technique, effectively capture such defects caused by spalling, aiding in comprehensive defect detection and action planning.

Following ISO standards, motor vibrations are measured during operation using a tri-axial accelerometer and a vibration analyzer. Employing high-resolution analysis, this process assesses rotor balancing, alignment with external loads (gearbox, compressor, pump, fan), eccentricity, soft foot problems, and bearing defects. Equipment like the Crystal Coco-80 Vibration Analyzer or SPM Diamond Analyzer ensures thorough analysis through time-based studies and frequency peak detection.

These tests, conducted using advanced equipment and following international standards, allow for the precise identification of motor issues while in operation, enabling timely maintenance interventions to ensure optimal motor performance and longevity.

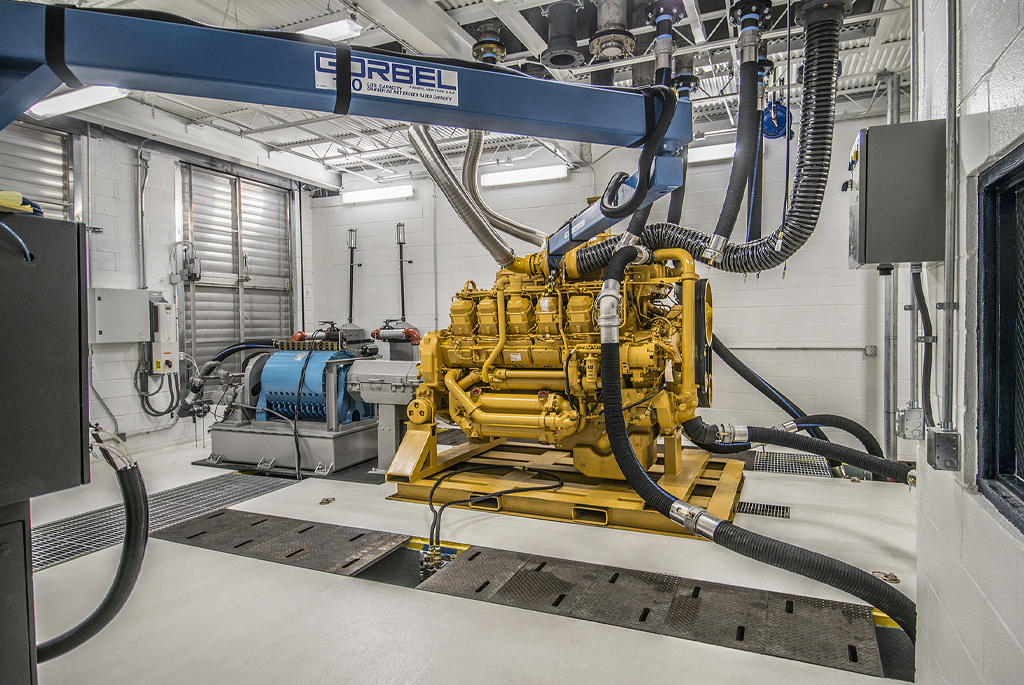

Unleashing power on the dyno, where engines roar and performance speaks louder than words:

Dyno testing, short for dynamometer testing, is a method used to evaluate the performance of an engine. Dyno testing will provide you information on your engine, and graphs of your engine’s performance. This lets you compare your engine performance with the results from the dyno so that you can make changes or improvements in the engine. In addition to torque and peak torque, the test also provides information on horsepower, volume metric efficiency, the temperatures of the cylinders and pistons, airflow. In short, measurements of almost every engine function are obtained from the test results.

Deluxe has a 2500HP dynamometer capacity to test your engine.

A load test will ensure that standby or prime generator will support your load when the occasion arises. Annual load testing is imperative to confirm your generator is capable of handling the demanded load when necessary Load Banks are electrical devices that are temporarily wired into a generator’s AC voltage output. Load is applied to the generator through switches that are calibrated to produce specific Kilowatt (Kw) output. This allows the operator to apply specific load steps during the testing process to match the generators rated capacity. This will help discovere any malfunctions in engine or in alternator. Problems discovered early can be significantly less expensive and prevents future major issues. Deluxe has 1500KVA Load Bank Testing capacity to test your generator.